P: +86-18866913099

E: sales01@latelas.com

E: sales01@latelas.com

NO 888 Maltsea Industrial Park, Mine Town, Lanling County, Linyi City, Shandong Province, China

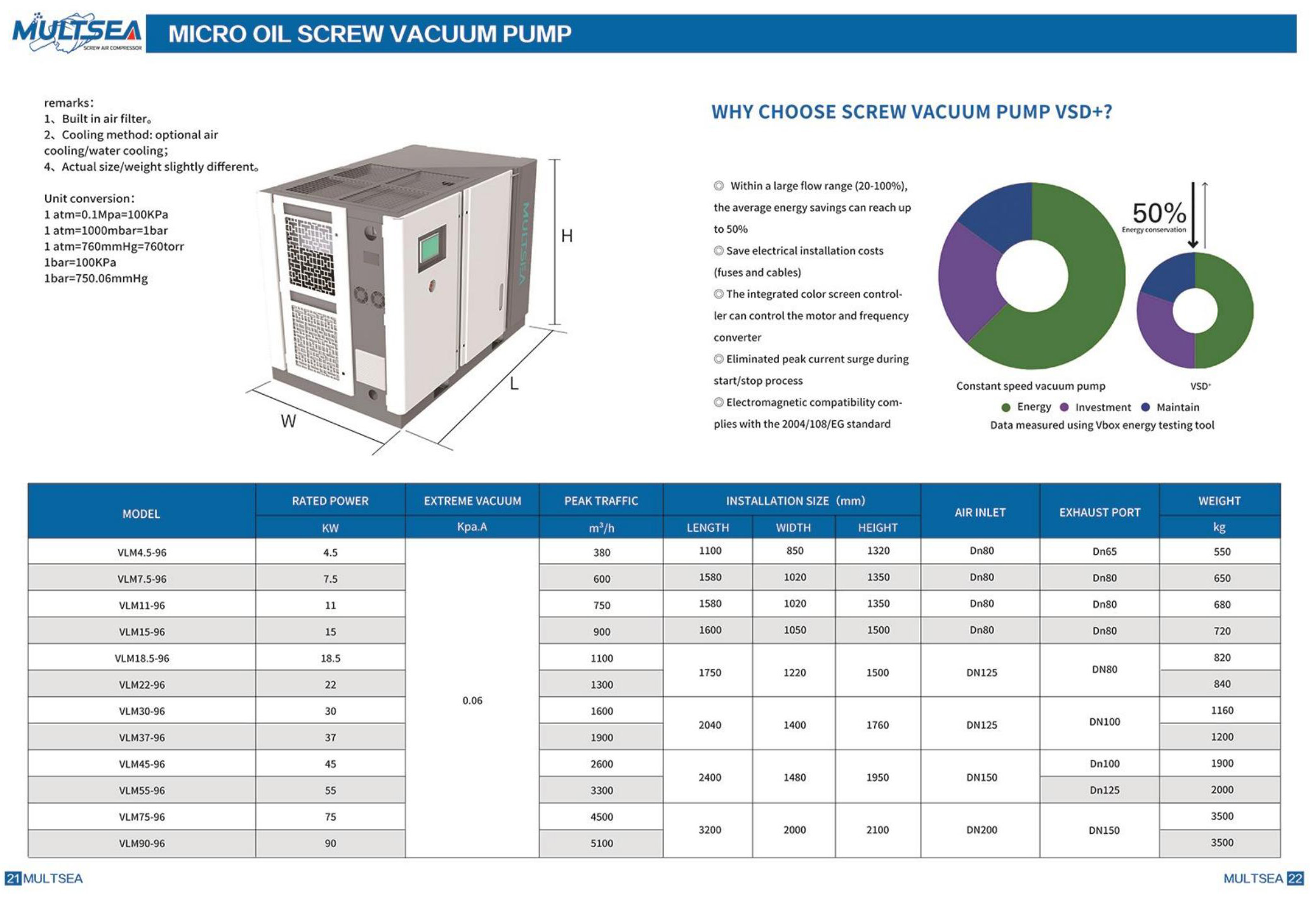

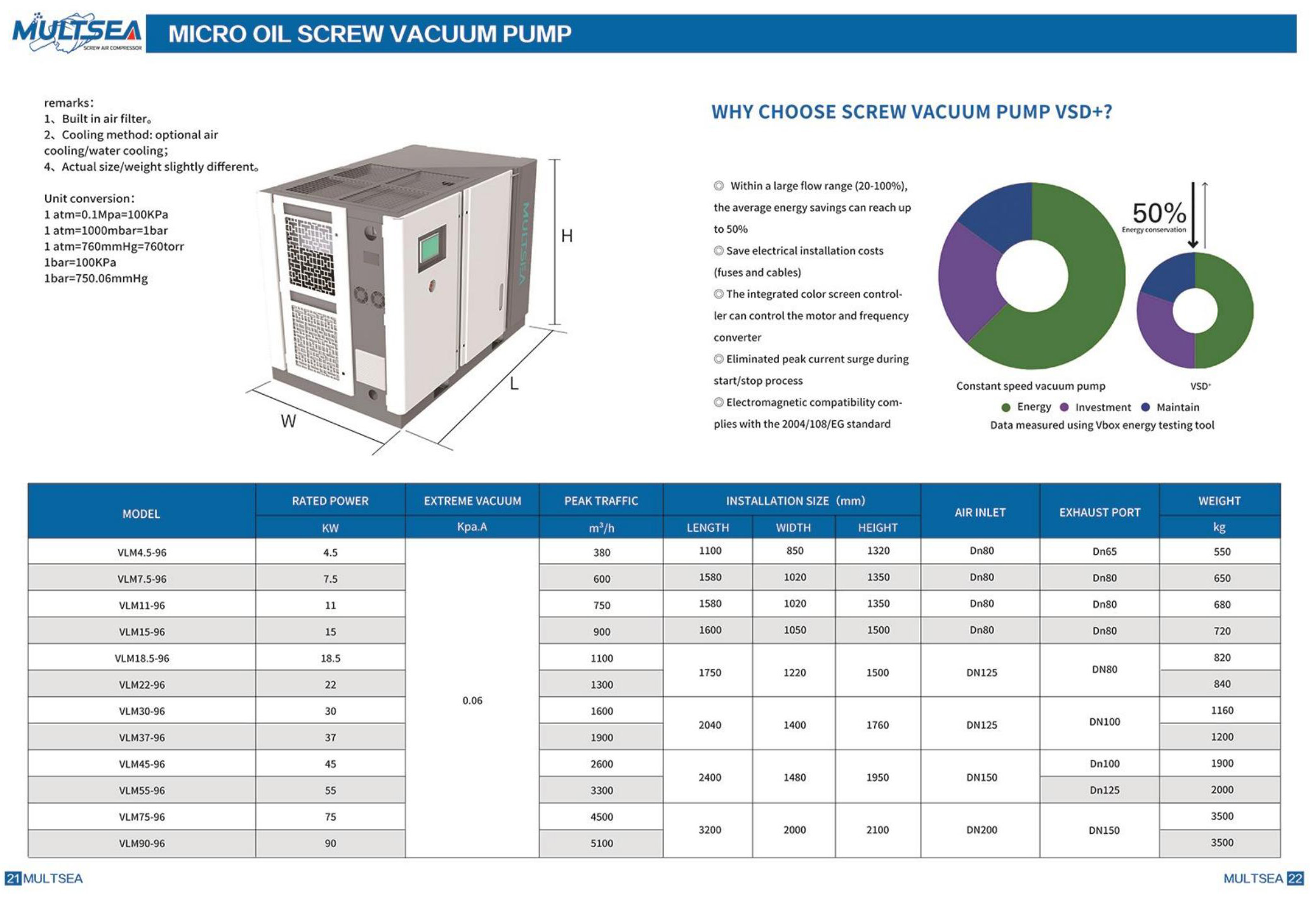

The MULTSEA Micro Oil Screw Vacuum Pump (VLM series) is designed for applications where moderate oil use (micro-lubrication), energy savings, and precision control are key—filling the gap between oil-free and fully oil-flooded pumps.

| Availability: | |

|---|---|

| Quantity: | |

Automotive Component Manufacturing: In brake disc machining or engine part casting, micro-oil lubrication reduces rotor wear (extending pump life) while avoiding excessive oil residue that could contaminate machined surfaces. The VLM’s stable vacuum (0.06 Kpa.A for VLM4.5-96) ensures consistent clamping of parts during CNC milling.

Chemical & Petrochemical Processing: For solvent recovery (e.g., ethanol or acetone) in chemical reactors, the VLM’s VSD+ system adjusts vacuum levels to match solvent volatility—preventing over-suction and reducing solvent loss. Its built-in air filter traps dust and chemical residues, protecting internal components.

Laboratory & Research Facilities: In material science labs (e.g., vacuum drying of polymers) or analytical equipment (e.g., mass spectrometers), the VLM’s quiet operation (≤70 dB) and precise pressure control (±0.1 Kpa) avoid disrupting experiments. Its compact size (1100×850×1320 mm for VLM4.5-96) fits under lab benches.

Printing & Packaging: For flexographic printing (where vacuum holds rolls of film in place), the VLM’s peak traffic (up to 5100 m³/h for VLM90-96) handles high-speed printing lines, while micro-oil lubrication reduces maintenance downtime compared to dry pumps.

VSD+ Energy Savings: Within a 20-100% flow range, the VLM’s variable speed drive (VSD+) delivers up to 50% average energy savings compared to fixed-speed vacuum pumps. It eliminates peak current surges during startup, protecting your electrical system and reducing fuse/cable sizing costs by 30%.

Micro-Oil Lubrication: A precise oil injection system uses minimal oil (≤5 ml/h) to lubricate rotors—reducing wear without oil carryover. This balances durability (5-7 year lifespan) and cleanliness, making it ideal for industries where oil-free pumps are too costly.

Integrated Smart Control: The color screen controller monitors motor speed, temperature, and pressure in real time, allowing one-touch adjustments. It also complies with the 2004/108/EG electromagnetic compatibility (EMC) standard, avoiding interference with nearby electronics (e.g., lab equipment).

Flexible Sizing & Cooling: With 11 models (VLM4.5-96 to VLM90-96), the VLM covers peak traffic from 380 m³/h to 5100 m³/h. Air or water cooling options adapt to environments from cool labs (15°C) to warm factories (45°C).

Q1: How is "micro-oil" different from fully oil-flooded pumps?

A1: Micro-oil pumps use 90% less oil than oil-flooded models, and a high-efficiency separator traps oil vapor—so no oil reaches your process. This avoids product contamination while still providing rotor lubrication (unlike dry pumps, which wear faster).

Q2: Does the VLM require special oil?

A2: Yes, use MULTSEA’s recommended food-grade or industrial-grade vacuum pump oil (depending on your industry). This oil is formulated to resist oxidation and maintain viscosity at high temperatures, ensuring optimal performance.

Q3: Can the VSD+ system be adjusted remotely?

A3: Yes, the VLM’s controller supports Modbus communication, allowing remote monitoring and adjustment via your factory’s SCADA system. This is ideal for facilities with multiple pumps or off-site management.

Q4: What maintenance is required for the VLM?

A4: Replace the air filter every 8 months, change the oil every 12 months, and clean the oil separator annually. Routine checks take <30 minutes, and the controller alerts you to maintenance needs—minimizing downtime.

Automotive Component Manufacturing: In brake disc machining or engine part casting, micro-oil lubrication reduces rotor wear (extending pump life) while avoiding excessive oil residue that could contaminate machined surfaces. The VLM’s stable vacuum (0.06 Kpa.A for VLM4.5-96) ensures consistent clamping of parts during CNC milling.

Chemical & Petrochemical Processing: For solvent recovery (e.g., ethanol or acetone) in chemical reactors, the VLM’s VSD+ system adjusts vacuum levels to match solvent volatility—preventing over-suction and reducing solvent loss. Its built-in air filter traps dust and chemical residues, protecting internal components.

Laboratory & Research Facilities: In material science labs (e.g., vacuum drying of polymers) or analytical equipment (e.g., mass spectrometers), the VLM’s quiet operation (≤70 dB) and precise pressure control (±0.1 Kpa) avoid disrupting experiments. Its compact size (1100×850×1320 mm for VLM4.5-96) fits under lab benches.

Printing & Packaging: For flexographic printing (where vacuum holds rolls of film in place), the VLM’s peak traffic (up to 5100 m³/h for VLM90-96) handles high-speed printing lines, while micro-oil lubrication reduces maintenance downtime compared to dry pumps.

VSD+ Energy Savings: Within a 20-100% flow range, the VLM’s variable speed drive (VSD+) delivers up to 50% average energy savings compared to fixed-speed vacuum pumps. It eliminates peak current surges during startup, protecting your electrical system and reducing fuse/cable sizing costs by 30%.

Micro-Oil Lubrication: A precise oil injection system uses minimal oil (≤5 ml/h) to lubricate rotors—reducing wear without oil carryover. This balances durability (5-7 year lifespan) and cleanliness, making it ideal for industries where oil-free pumps are too costly.

Integrated Smart Control: The color screen controller monitors motor speed, temperature, and pressure in real time, allowing one-touch adjustments. It also complies with the 2004/108/EG electromagnetic compatibility (EMC) standard, avoiding interference with nearby electronics (e.g., lab equipment).

Flexible Sizing & Cooling: With 11 models (VLM4.5-96 to VLM90-96), the VLM covers peak traffic from 380 m³/h to 5100 m³/h. Air or water cooling options adapt to environments from cool labs (15°C) to warm factories (45°C).

Q1: How is "micro-oil" different from fully oil-flooded pumps?

A1: Micro-oil pumps use 90% less oil than oil-flooded models, and a high-efficiency separator traps oil vapor—so no oil reaches your process. This avoids product contamination while still providing rotor lubrication (unlike dry pumps, which wear faster).

Q2: Does the VLM require special oil?

A2: Yes, use MULTSEA’s recommended food-grade or industrial-grade vacuum pump oil (depending on your industry). This oil is formulated to resist oxidation and maintain viscosity at high temperatures, ensuring optimal performance.

Q3: Can the VSD+ system be adjusted remotely?

A3: Yes, the VLM’s controller supports Modbus communication, allowing remote monitoring and adjustment via your factory’s SCADA system. This is ideal for facilities with multiple pumps or off-site management.

Q4: What maintenance is required for the VLM?

A4: Replace the air filter every 8 months, change the oil every 12 months, and clean the oil separator annually. Routine checks take <30 minutes, and the controller alerts you to maintenance needs—minimizing downtime.