P: +86-18866913099

E: sales01@latelas.com

E: sales01@latelas.com

NO 888 Maltsea Industrial Park, Mine Town, Lanling County, Linyi City, Shandong Province, China

| Availability: | |

|---|---|

| Quantity: | |

The ZGM series single stage variable frequency stationary screw air compressor is an energy-saving, intelligent air supply solution for industrial scenarios requiring stable pressure and variable air demand. It integrates IE5 class permanent magnet variable frequency motors, self-developed high-performance air ends, and smart IoT systems, achieving “on-demand air supply” — reducing energy consumption by 30-50% compared to fixed-speed models. With 15 models (ZGM7.5 to ZGM250) covering 7.5-250 kW motor power, free air delivery of 0.7-43.6 m³/min, and pressure of 0.8-1.25 MPa, it is widely used in precision manufacturing, continuous automation, and large-scale spraying facilities.

Precision industries (e.g., semiconductor packaging, medical device assembly) require ultra-stable air pressure (fluctuation ≤±0.02 MPa) to avoid product defects. The ZGM series’ vector frequency conversion technology adjusts motor speed in real time based on air demand, maintaining constant pressure. Its IE5 permanent magnet motor (efficiency ≥97%) ensures low heat generation, avoiding pressure instability caused by motor overheating — critical for high-precision processes.

Automated warehouses (with pneumatic conveyors) or bottle-filling lines often have variable air demand (e.g., peak demand during shift changes, low demand at night). The ZGM series’ frequency conversion startup eliminates energy waste from “idle operation” of fixed-speed compressors; its smart IoT system monitors real-time energy consumption, providing data reports to optimize operation schedules (e.g., reducing speed during low-demand periods).

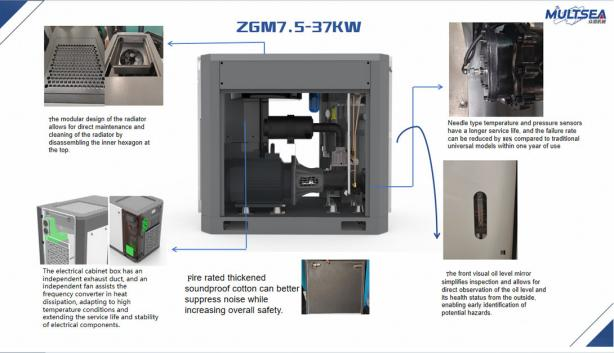

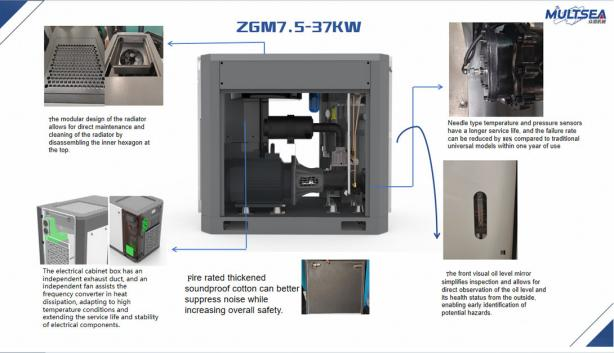

Large spraying plants (e.g., automotive coating lines) require low noise and high safety. The ZGM series uses fire-rated thickened soundproof cotton (noise 68-88 dB) to meet workplace noise standards; its independent intake channel connects directly to air filters, reducing intake temperature by 5-8℃ and improving air delivery efficiency. The filter cotton is installed on an independent partition, allowing external replacement without stopping the machine — minimizing production downtime.

• Variable Frequency Energy Saving: IE5 class IP55 split-type permanent magnet motor + vector frequency conversion technology, adapting to 10-100% air demand and saving energy costs significantly.

• Smart IoT Integration: Supports real-time data propagation (pressure, temperature, energy consumption) via cloud servers; remote monitoring via mobile/PC clients, enabling predictive maintenance (e.g., alerting for filter replacement).

• High Safety & Low Noise: Fire-rated thickened soundproof cotton + IP55 motor protection (dustproof, waterproof); meets global safety standards (ISO, CE).

• Long Warranty: 5-year warranty for self-developed main engines, 18-month whole-machine warranty — reducing long-term investment risks.

• IE5 Permanent Magnet Motor: IP55 protection class, suitable for humid/dusty environments; split-type design for easy maintenance; service factor SF=1.2, ensuring overload capacity.

• Intelligent Control Panel: Advanced touch screen with fault warning (e.g., high oil temperature, filter clogging), multi-language display (English, Spanish, German), and real-time energy consumption statistics.

• Heat Dissipation System: Electrical cabinet with independent exhaust duct + auxiliary fan for frequency converter cooling, adapting to high-temperature environments (≤50℃) and extending component life.

• Oil & Gas Separation: New stainless steel oil-air separation barrels with high-efficiency separation cores, reducing oil carryover to ≤2 ppm — protecting downstream equipment and improving air quality.

• Smart Remote Support: Cloud-based fault diagnosis (engineers can analyze data remotely to identify issues); provide real-time technical guidance via video calls.

• OEM Customization: Professional design team supports OEM orders (e.g., custom logos, special voltage configurations); deliver customized models within 45-60 days.

• Spare Parts & Maintenance: Global spare parts network (warehouses in Europe, North America, Asia) ensures replacement parts arrive within 48 hours; provide annual maintenance training for customers’ maintenance teams.

• Energy Audit: Offer free energy audit services for existing air systems, providing optimization suggestions (e.g., matching ZGM models to reduce energy waste).

The ZGM series single stage variable frequency stationary screw air compressor is an energy-saving, intelligent air supply solution for industrial scenarios requiring stable pressure and variable air demand. It integrates IE5 class permanent magnet variable frequency motors, self-developed high-performance air ends, and smart IoT systems, achieving “on-demand air supply” — reducing energy consumption by 30-50% compared to fixed-speed models. With 15 models (ZGM7.5 to ZGM250) covering 7.5-250 kW motor power, free air delivery of 0.7-43.6 m³/min, and pressure of 0.8-1.25 MPa, it is widely used in precision manufacturing, continuous automation, and large-scale spraying facilities.

Precision industries (e.g., semiconductor packaging, medical device assembly) require ultra-stable air pressure (fluctuation ≤±0.02 MPa) to avoid product defects. The ZGM series’ vector frequency conversion technology adjusts motor speed in real time based on air demand, maintaining constant pressure. Its IE5 permanent magnet motor (efficiency ≥97%) ensures low heat generation, avoiding pressure instability caused by motor overheating — critical for high-precision processes.

Automated warehouses (with pneumatic conveyors) or bottle-filling lines often have variable air demand (e.g., peak demand during shift changes, low demand at night). The ZGM series’ frequency conversion startup eliminates energy waste from “idle operation” of fixed-speed compressors; its smart IoT system monitors real-time energy consumption, providing data reports to optimize operation schedules (e.g., reducing speed during low-demand periods).

Large spraying plants (e.g., automotive coating lines) require low noise and high safety. The ZGM series uses fire-rated thickened soundproof cotton (noise 68-88 dB) to meet workplace noise standards; its independent intake channel connects directly to air filters, reducing intake temperature by 5-8℃ and improving air delivery efficiency. The filter cotton is installed on an independent partition, allowing external replacement without stopping the machine — minimizing production downtime.

• Variable Frequency Energy Saving: IE5 class IP55 split-type permanent magnet motor + vector frequency conversion technology, adapting to 10-100% air demand and saving energy costs significantly.

• Smart IoT Integration: Supports real-time data propagation (pressure, temperature, energy consumption) via cloud servers; remote monitoring via mobile/PC clients, enabling predictive maintenance (e.g., alerting for filter replacement).

• High Safety & Low Noise: Fire-rated thickened soundproof cotton + IP55 motor protection (dustproof, waterproof); meets global safety standards (ISO, CE).

• Long Warranty: 5-year warranty for self-developed main engines, 18-month whole-machine warranty — reducing long-term investment risks.

• IE5 Permanent Magnet Motor: IP55 protection class, suitable for humid/dusty environments; split-type design for easy maintenance; service factor SF=1.2, ensuring overload capacity.

• Intelligent Control Panel: Advanced touch screen with fault warning (e.g., high oil temperature, filter clogging), multi-language display (English, Spanish, German), and real-time energy consumption statistics.

• Heat Dissipation System: Electrical cabinet with independent exhaust duct + auxiliary fan for frequency converter cooling, adapting to high-temperature environments (≤50℃) and extending component life.

• Oil & Gas Separation: New stainless steel oil-air separation barrels with high-efficiency separation cores, reducing oil carryover to ≤2 ppm — protecting downstream equipment and improving air quality.

• Smart Remote Support: Cloud-based fault diagnosis (engineers can analyze data remotely to identify issues); provide real-time technical guidance via video calls.

• OEM Customization: Professional design team supports OEM orders (e.g., custom logos, special voltage configurations); deliver customized models within 45-60 days.

• Spare Parts & Maintenance: Global spare parts network (warehouses in Europe, North America, Asia) ensures replacement parts arrive within 48 hours; provide annual maintenance training for customers’ maintenance teams.

• Energy Audit: Offer free energy audit services for existing air systems, providing optimization suggestions (e.g., matching ZGM models to reduce energy waste).

Q1: Are you factory or trade company?

A1: We are factory. Please check Our Company Profile.

Q2: What the exactly address of your factory?

A2: Mengshan Innovation Park, Zaoyuan Town, Linyi, Shandong, China

Q3: Warranty terms of your machine?

A3: 18 months warranty for the machine,technical support according to your needs.

Q4: Will you provide some spare parts of the machines?

A4: Yes.

Q5: How long will you take to arrange production?

A5: Deliver standard goods within 30days, Other customized goods is TBD.

Q6: Can you accept OEM orders?

A6: Yes, with professional design team, OEM orders are highly welcome.

Contact us.

Q1: Are you factory or trade company?

A1: We are factory. Please check Our Company Profile.

Q2: What the exactly address of your factory?

A2: Mengshan Innovation Park, Zaoyuan Town, Linyi, Shandong, China

Q3: Warranty terms of your machine?

A3: 18 months warranty for the machine,technical support according to your needs.

Q4: Will you provide some spare parts of the machines?

A4: Yes.

Q5: How long will you take to arrange production?

A5: Deliver standard goods within 30days, Other customized goods is TBD.

Q6: Can you accept OEM orders?

A6: Yes, with professional design team, OEM orders are highly welcome.

Contact us.